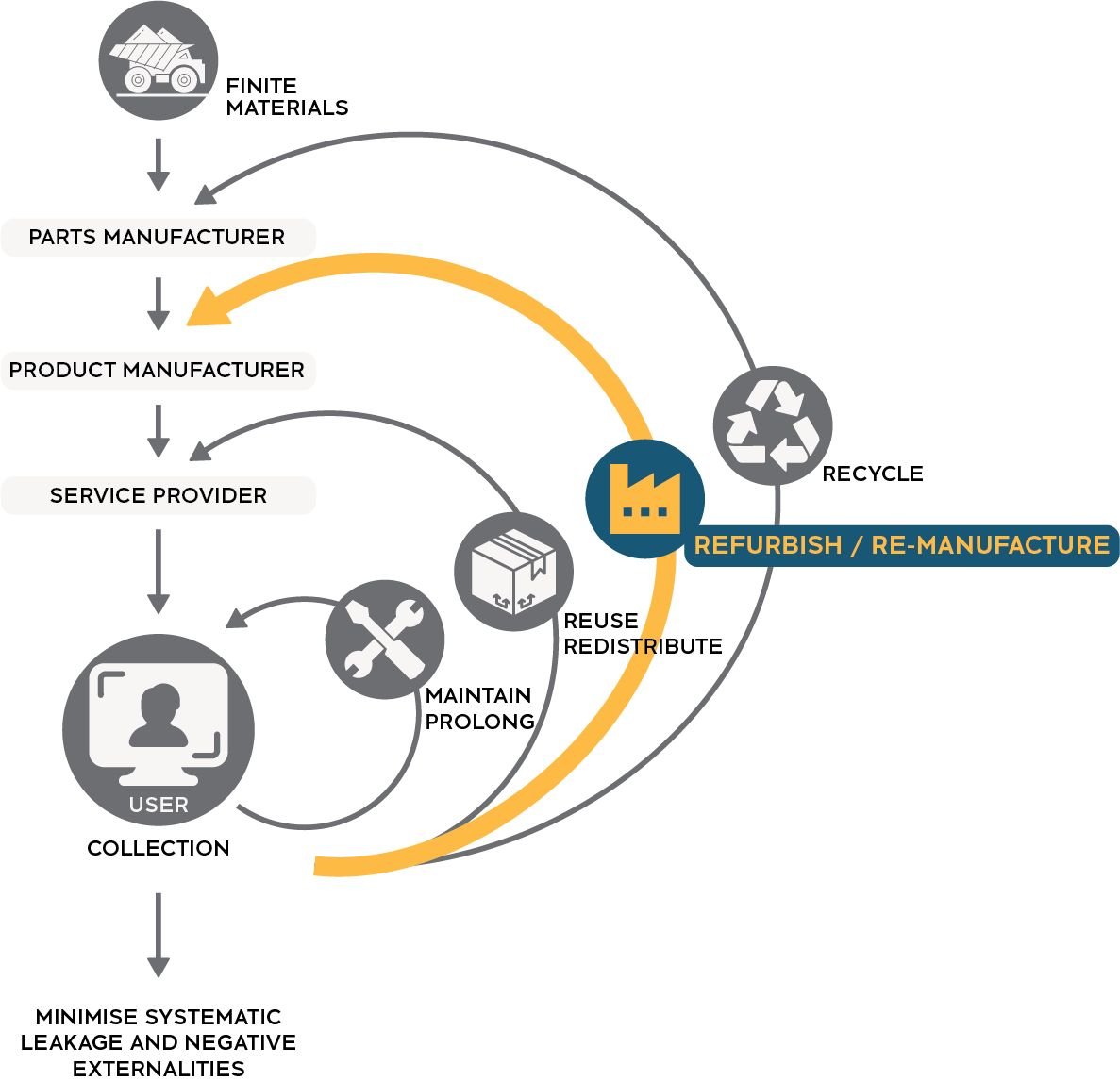

WorkbenchX simplifies the journey for equipment users and original component manufacturers by increasing the number of circular value retention loops a product undergoes before reaching its end of life. By doing so, scarce raw materials are circulated for multiple life cycles, conserving up to 80% or more of the original raw materials, labor, and embedded energy.

Driving Circular Industrial Economy: WorkbenchX accelerating the transition

Maximizing the life cycle value of end-use industrial components poses significant challenges due to the uncertain conditions and expensive processes to find and manage service providers.

WorkbenchX simplifies the journey for equipment users and original component manufacturers by increasing the number of circular value retention loops a product undergoes before reaching its end of life. By doing so, scarce raw materials are circulated for multiple life cycles, conserving up to 80% or more of the original raw materials, labor, and embedded energy.

WorkbenchX streamlines the remanufacturing process through automation and AI, making it more efficient and cost-effective for equipment users; thus, reduces waste and contributes to significant reduction in carbon emissions.

A case study highlighted the environmental benefits of remanufacturing, with a remanufactured industrial bearing requiring significantly 60% fewer resources and resulting in 85% less greenhouse gas emissions than manufacturing a new one. Such examples underscore the transformative potential of circular asset management strategies facilitated by WorkbenchX.

At its core, WorkbenchX is driven by a mission to accelerate the world's transition to a circular industrial economy. With a vision to become the most sustainable company that maximizes the lifecycle value of industrial products, the platform serves as a supply chain hub, connecting OEMs, equipment users, and service providers to build a circular economy ecosystem.

Led by co-founder and CEO Joe Ayrookaran, a visionary in circular economy innovation, WorkbenchX brings together expertise in repair, remanufacturing, and supply chain management. Joe's extensive executive experience, spanning sectors from semiconductors to mining technology, underscores his commitment to driving sustainable solutions and shaping a more circular future.

As WorkbenchX continues to pave the way for circular economy practices, it stands as a beacon of change, guiding industries toward a more sustainable and resource-efficient future. WorkbenchX is reshaping the industrial equipment landscape through collaboration and innovation, one component at a time.